Simplified: The European Standard for Cut-Resistant Gloves

Globally, there are two different performance standards for cut resistance. The European standard (EN 388:2016) is used in Europe, Asia, South America, Australia, Mexico, and even parts of Canada and the United States. The ANSI/ISEA 105-2016 is the US standard for glove testing but is also used in other parts of North America as well.

These standards are not identical and do not correlate, which can potentially cause confusion when you’re trying to select the right Bob Dale Gloves cut-resistant work gloves for your specific workplace application.

The purpose of this blog is to explain the EN 388:2016 cut standard (the primary standard used in Canada), as well as its testing methodology, in order to set your expectations for performance and cut resistance when choosing Bob Dale Gloves Cut-Resistant Gloves for your workplace.

If you would like to learn more about the North American standard (ANSI/ISEA 105-2016) for cut-resistant gloves, please check out this blog post.

What is the EN 388:2016 standard for cut-resistant gloves?

EN 388:2016 is the cut-resistant gloves standard used in Europe, Asia, South America, Australia, Mexico, and even parts of Canada and the US. It establishes glove protection performance levels, testing, and classification for fabric or layers of fabric for their ability to resist cutting by a blade.

What does the EN 388:2016 cut test entail?

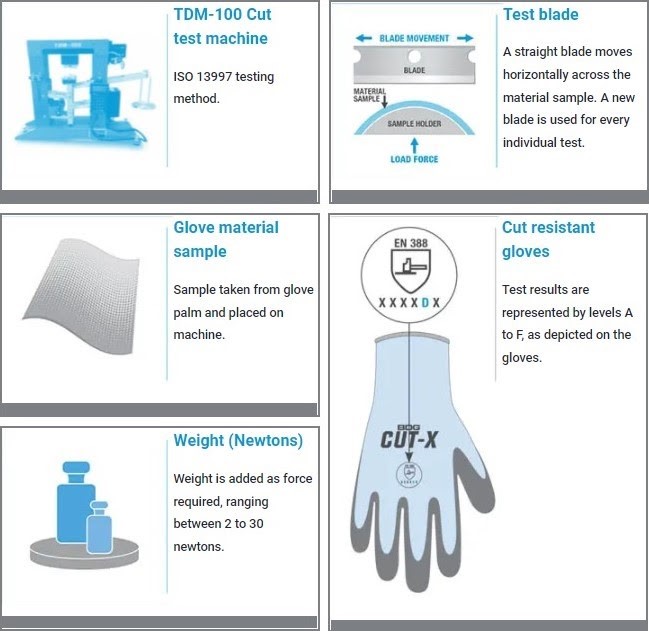

The EN 388:2016 standard uses both the Coupe Test (rotating blade) and the ISO 13997 Test (using a TDM-100 machine) to measure cut resistance.

The Coupe Test gives a cut score of 1-5 and is used for lower cut-resistant materials. But if the Coupe Test results in a score of 3-5, then the ISO 13997 Test is required.

The ISO 13997 Test uses a Tomodynamometer (TDM-100) machine to measure the amount of weight (newtons) necessary for a blade to cut through the material. The blade is replaced after each cut and weight is added as force until cut-through is obtained. Multiple tests are conducted – ranging from 2 to 30 newtons of force. The ISO 13997 test produces a score measured in newtons from A to F, with F being the highest level of cut resistance.

What level of Bob Dale Gloves Cut-Resistant Gloves do I need for my specific application?

We’ve compiled a list of common workplace applications and grouped them according to the approximate protection levels required. Please note that this is only a general guide, as every job has many variables that might call for either greater or less protection.

While some gloves may require more or less cut resistance for the job at hand, level 4 cut resistant gloves or higher (EN Cut level D) would be considered a high cut level glove. EN Cut Level E would correspond with level 5 cut resistant gloves and EN Cut Level F corresponds with level 7 on the ANSI/ISEA 105-2016 chart.

What exactly is a Tomodynamometer?

A Tomodynamometer (TDM-100) cut test machine is designed to measure the cut resistance of materials without the influence of sample thickness or direction of blade motion. The tester consists of a straight blade that is drawn across the sample mounted on a curved surface. The cut resistance measuring device operates on the principle of applying varying loads to a straight-edged blade and recording the distance required to cut through the sample. The testing result is calculated of a cutting load at a specified reference distance using a regression procedure.

What are the direct and indirect costs associated with a workplace hand injury for the employer?

Every year, hand injuries result in more than a million emergency room visits, making them the second-most common work-related injury, according to the US Bureau of Labor Statistics (BLS). The most important reason to reduce these numbers is worker health and safety. But a compelling business case for accident prevention exists, too. The direct costs of hand injuries are very high, but the indirect costs – such as lost productivity, training for replacement workers, and even negative publicity – are even higher.

Here are some sobering statistics from a study appearing in Journal of Bone and Joint Surgery:

These are only the tip of the iceberg. According to the American Society of Safety Engineers, indirect costs of injuries can be up to 20 times the direct costs. Other indirect, virtually incalculable costs can include the expense of investigating the accident, lost worker productivity, damage to workers’ morale that leads to absenteeism, and a negative impact on the company’s reputation.

What is High-Performance Polyethylene (HPPE)?

While stainless steel and aramid are sometimes used to reinforce safety gloves, HPPE is a preferred material found in hand protection. HPPE fiber (sometimes referred to by the brand names Dyneema and Spectra) has an ultra-high strength-to-weight ratio, so it’s not only flexible and lightweight but also highly durable.

Pound-for-pound, HPPE is up to 15x stronger than steel, providing excellent protection from both abrasion injuries and cut injuries. Many styles of Bob Dale Gloves Cut-Resistant Gloves are made with HPPE because it offers an ideal combination of:

Where can I purchase Bob Dale Gloves Cut-Resistant Gloves?

Hazmasters and Bob Dale Gloves are proud to partner together to bring you a comprehensive line of cut-resistant gloves. You can also order from our complete supply of Bob Dale Gloves Cut-Resistant Gloves at Hazmasters.com.

| Call Us : Sales & Service: (877) 747-7117 Corporate: (800) 434-7065 |